Frequently Asked Questions

1. What are the different types of bearings?

2. What is the main function of bearings?

3. What factors should I consider when choosing bearings?

4. What are the benefits of Pillow Block Bearings?

5. How important is lubrication in bearing maintenance?

When it comes to mechanical applications, selecting the right type of bearings is crucial for optimal performance and longevity. Bearings facilitate smooth movement by reducing friction between moving parts, and different types are designed for specific conditions and loads. This guide will discuss how to choose the right bearings, including the much-valued Pillow Block Bearing, to ensure your machinery runs efficiently.

Understanding Bearing Basics

Bearings are essential components in various machines, from household appliances to industrial machinery. They serve multiple purposes, such as supporting loads, enabling rotary or linear motion, and absorbing shock and vibrations. The choice of bearings significantly affects the performance, efficiency, and reliability of your application.

Types of Bearings

There are numerous types of bearings available, each designed for specific applications. Some of the most commonly used types include:

- Ball Bearings: These are versatile and are used in applications requiring low friction and reduced running temperatures.

- Roller Bearings: A great choice for heavy loads, these bearings can handle significant radial loads and are often used in heavy machinery.

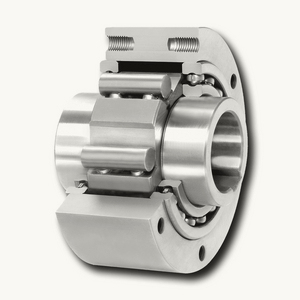

- Pillow Block Bearings: Ideal for supporting rotating shafts in various applications, Pillow Block Bearings are designed for easy installation and removal, making them popular in manufacturing setups.

- Thrust Bearings: Used to support axial loads, these bearings are ideal for applications where the primary load direction is axial.

- Magnetic Bearings: Employing magnetic levitation, these bearings reduce friction significantly and are used in precision applications.

Factors to Consider When Choosing Bearings

When selecting bearings for your application, several critical factors should be taken into account:

Load Capacity

The load that a bearing needs to support is one of the primary considerations. Understanding the maximum load capacity and the type of load (radial or axial) is essential. For example, a Pillow Block Bearing is often chosen for its load-bearing capabilities in applications that experience significant sideways stresses.

Speed

Each bearing type has a maximum speed rating. For applications involving high speeds, such as in fans or motors, selecting bearings that can handle the required speed without overheating is vital. Always check the manufacturer's specifications to ensure compatibility with your speed requirements.

Environmental Conditions

The operating environment can drastically affect bearing performance. Factors such as temperature, humidity, and the presence of contaminants can impact the longevity and functionality of bearings. Look for bearings that are designed to withstand such conditions; for instance, Pillow Block Bearings are typically housed in a robust casing, providing excellent protection in harsher environments.

Alignment

Misalignment can cause premature bearing failure. Ensure that you’re choosing bearings suited for misalignment tolerance, especially in rotating applications. For instance, self-aligning ball bearings, which can adjust to slight misalignments, may be a smart choice in such cases.

Pillow Block Bearings in Detail

Pillow Block Bearings are particularly noteworthy due to their versatility and ease of use. Designed to support rotating shafts, they are typically mounted on a base and provide a convenient solution for frequent maintenance and adjustments. Here are some of the benefits and potential applications of Pillow Block Bearings:

Benefits of Pillow Block Bearings

- Easy Installation: Pillow Block Bearings are designed for quick installation and removal, making them an excellent choice for machinery that requires frequent maintenance.

- Robust Support: They are capable of handling both radial and axial loads, providing versatile support for a variety of applications.

- Adaptable Design: They come in various sizes and specifications, allowing you to choose a model that fits your unique requirements.

Applications of Pillow Block Bearings

Pillow Block Bearings are commonplace in multiple industries and applications, including:

- Conveyor systems

- Manufacturing equipment

- Transportation equipment

- Textile machinery

- Agricultural machines

Material Considerations

The materials used in bearing manufacturing play a significant role in performance, durability, and efficiency. Common materials include steel, plastic, and ceramic. Each has its advantages depending on the application:

Steel Bearings

Steel is a popular choice for many types of bearings due to its strength and durability. Steel bearings can handle significant loads and high speeds but may rust or corrode in humid environments. Proper lubrication can mitigate these concerns.

Plastic Bearings

Plastic bearings are lightweight and provide excellent chemical resistance, making them ideal for applications in harsh environments. However, they may not support as high a load as steel bearings.

Ceramic Bearings

Ceramic bearings are known for their resistance to corrosion, high temperatures, and wear. They are often used in high-performance applications but come at a higher price point.

Lubrication Matters

Proper lubrication plays a vital role in extending the life of any bearing. Insufficient lubrication can result in increased friction, heat, and wear, ultimately leading to early failure. There are two primary types of lubrication:

Grease Lubrication

Grease is commonly used in many applications due to its ability to stay in place longer than oil. It also provides a barrier against contaminants, making it a preferred choice for rugged environments.

Oil Lubrication

Oil is typically used in high-speed applications, as it provides superior cooling and can reach areas of the bearing that grease might not. However, oil may require more frequent replenishment and regular monitoring of levels.

User Guidelines for Maintenance

Regular maintenance is essential for maximising the performance and lifespan of bearings. Here are practical tips for maintaining the bearings in your application:

- Check Lubrication: Regularly inspect lubrication levels and quality. Replace or replenish as necessary.

- Monitor Temperature: Increased operating temperatures can indicate friction problems or insufficient lubrication.

- Inspect for Wear: Look for signs of wear and tear on bearings, including discoloration or unusual noises.

- Maintaining Cleanliness: Ensure the bearing area is free from debris and contaminants that can hinder operation.

Making the Final Decision

Choosing the right type of bearing for your specific application may seem daunting, but breaking down the process into manageable steps can simplify the task. Whether it’s opting for a robust Pillow Block Bearing or a high-speed ball bearing, understanding the factors that influence performance and durability—such as load capacity, environmental conditions, materials, and maintenance—will lead you to an informed decision.

By considering these factors, you can ensure that your machinery operates smoothly, efficiently, and reliably, ultimately boosting productivity and longevity. Remember to regularly assess and maintain your bearings, adapting as necessary to ensure optimal operation in your specific application. The right investment in bearing technology can significantly benefit your overall machinery performance.

Linked Product

VXB 3/4 Bearing UCP204-12 + Pillow Block Cast Housing Mounted Bearing

The VXB UCP204-12 Pillow Block Bearing offers a reliable solution for various applications with its robust design and high load capacity. Featuring a 3/4" inner diameter and a set screw type for secure mounting, it is suitable for use in machinery where a stable bearing support is required. Its durable cast housing ensures longevity and consistent performance in demanding environments.

View Product