Frequently Asked Questions

1. What role do bearings play in machinery?

2. What is the UCP204-12 bearing?

3. Why is the quality of bearings important?

4. How can one identify quality bearings?

5. What maintenance practices are recommended for bearings?

In the realm of mechanical performance, bearings function as the unsung heroes that enable machinery to operate smoothly and efficiently. When one mentions bearings, the term often conjures up images of small, metal components, yet their role is monumental in various applications, from automotive to industrial machinery. Among the myriad of bearings available today, the UCP204-12 bearing stands out due to its unique specifications and reliability. This article delves into the vital importance of quality bearings and how they impact mechanical performance.

Understanding Bearings: A Brief Overview

Bearings are mechanical components that facilitate rotational or linear movement while reducing friction and supporting loads. By providing a smooth surface for motion, bearings significantly increase the lifespan and efficiency of machinery. There are numerous types of bearings, each designed for specific applications—ranging from ball bearings to roller bearings, and more. The UCP204-12 bearing is particularly noteworthy, commonly used in a variety of equipment due to its robust design and functionality.

The Mechanics Behind Bearings

The functionality of bearings can be encapsulated in three primary components: the inner race, outer race, and rolling elements (balls or rollers). When the internal mechanism rotates, it allows for significant reductions in friction, leading to improved mechanical efficiency. The seamless interaction between these components ensures durability and performance in various conditions.

Why Quality Matters in Bearings

Subpar bearings can lead to a cascade of mechanical failures, excessive downtime, and safety hazards. Here are some key factors highlighting the importance of quality bearings:

- Performance and Reliability: Quality bearings, like the UCP204-12 bearing, demonstrate superior performance by maintaining proper alignment and reducing wear over time.

- Operational Efficiency: High-quality bearings contribute to lower energy consumption, which translates to cost savings for businesses in the long run.

- Longevity: Investing in quality bearings increases the lifespan of machinery. Cheaper alternatives may save money upfront but can result in higher replacement costs and operational downtime.

Identifying Quality Bearings

To ensure optimum performance, one should consider several factors when selecting bearings:

- Material: Bearings made from high-grade materials such as stainless steel or ceramic offer enhanced durability and resistance to corrosive environments.

- Manufacturing Standards: Look for bearings that adhere to strict industry standards. Quality control checks during production are essential for performance reliability.

- Design Features: Bearings like the UCP204-12 are designed for specific applications. Understanding the requirements of your machinery can dictate which bearing design is optimal.

The Consequences of Using Poor Quality Bearings

The repercussions of selecting inferior bearings can be serious. Here’s a closer look at what can happen:

Increased Friction and Heat

Poor-quality bearings often lead to excessive friction, causing increased heat generation. This not only reduces the efficiency of the machinery but can also lead to catastrophic failures if not addressed swiftly.

Reduced Load Capacity

Inferior bearings struggle to handle load demands, causing premature wear and failures. The UCP204-12 bearing, by contrast, is engineered to support significant loads, mitigating this issue effectively.

Higher Maintenance Costs

Using low-quality bearings typically results in the need for more frequent repairs and replacements. This increases overall maintenance costs and can severely affect production timelines.

Applications of Quality Bearings

Quality bearings permeate multiple sectors, and their applications are dynamically varied. Here’s how they play a role in different fields:

Automotive Industry

In automotive systems, quality bearings are critical for ensuring smooth wheel rotation and enhanced vehicle stability. They reduce mechanical noise and improve fuel efficiency, making them indispensable for modern vehicles.

Industrial Machinery

Whether in conveyor systems, pumps, or robotics, bearings serve essential functions in industrial settings. They enable reliability and precision in operations, significantly enhancing productivity.

Aerospace and Defence

Extreme conditions in aerospace applications require bearings that guarantee performance under pressure. Quality bearings are crucial for ensuring safety and reliability in aircraft and defence systems.

Quality Bearings: A Wise Investment

Investing in high-quality bearings should be viewed as a long-term strategy. The advantages far outweigh the costs associated with inferior products. By selecting bearings like the UCP204-12 bearing, businesses can set themselves up for greater success through:

- Improved Performance: Quality bearings maintain optimal performance even under challenging conditions.

- Reduced Downtime: Reliability translates into fewer mechanical failures and less interruption in production.

- Increased Profitability: With greater efficiency and lower maintenance needs, businesses can experience greater profit margins.

How to Ensure You’re Buying Quality Bearings

When it comes to purchasing bearings, understanding how to discern quality is essential. Here are some practical tips to assist you:

Research Different Manufacturers

Different manufacturers have varying reputations regarding quality control and reliability. Look for those with positive reviews and proven track records.

Seek Expert Advice

Consultation with industry experts can provide valuable insights into the best types of bearings for specific applications. Their recommendations often lead to improved performance outcomes.

Check Certifications and Standards

Bearings should comply with international manufacturing standards. Certificates can provide assurance that you are making a quality investment.

Maintaining Your Bearings for Optimal Performance

The journey doesn’t end with the purchase of quality bearings. Regular maintenance is paramount to ensuring they deliver consistent performance. Here are some maintenance tips:

- Regular Inspections: Schedule routine inspections to identify early signs of wear or damage.

- Lubrication: Apply appropriate lubricants as needed to prevent friction and overheating.

- Cleaning: Keep the area around bearings clean to avoid contamination that could impact performance.

Final Thoughts: Quality Bearings Drive Mechanical Excellence

In conclusion, the importance of quality bearings in mechanical performance cannot be overstated. As critical components across various industries, investing in high-quality options such as the UCP204-12 bearing ensures smoother operations, reduced downtime, and long-term savings. By prioritising quality in your bearing selections and maintenance, you can guarantee the reliability and efficiency of your machinery, ultimately driving success in your endeavours.

Linked Product

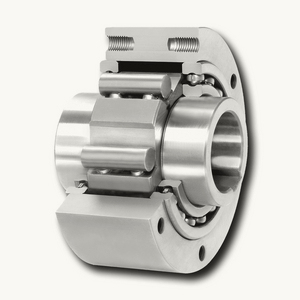

VXB 3/4 Bearing UCP204-12 + Pillow Block Cast Housing Mounted Bearing

The VXB UCP204-12 Pillow Block Bearing features a robust set screw design and is mounted within a durable cast housing, making it suitable for various applications requiring reliable support. With a 3/4" inner diameter and a high center height, it is designed to accommodate significant loads while maintaining stability. This bearing is ideal for machinery and equipment that demand consistent performance under varying conditions.

View Product