Overview

Bearings are essential mechanical components that reduce friction and support loads, facilitating smooth movement in various machinery and devices. This guide covers the types of bearings, their functions, applications across industries like automotive and aerospace, and key considerations for selecting and maintaining them for optimal performance. Understanding bearings is crucial for efficient machinery operation and longevity.

Frequently Asked Questions

1. What are bearings?

2. What are the key components of bearings?

3. What types of bearings are commonly used?

4. What factors should be considered when choosing a bearing?

5. How can bearings be maintained for optimal performance?

Bearings are essential components in various mechanisms, enabling smooth and efficient operation of machinery, vehicles, and everyday devices. For those new to mechanical engineering or those looking to enhance their practical knowledge, this comprehensive guide will help you understand the basics of bearings, their types, functions, applications, and how to choose the right bearing for your needs.

What are Bearings?

At its core, a bearing is a mechanical element that reduces friction between moving parts and supports loads. They facilitate the smooth rotation or linear movement of components, making them crucial in the efficiency of machines and vehicles. The critical role they play extends across multiple industries, from automotive to aerospace, and even in household appliances.

The Basic Functionality of Bearings

Bearings function by allowing one part to rotate or move over another with minimal friction. This is achieved using a small ball, roller, or other shapes that create a small gap between the moving parts. The gap is typically filled with lubricant, further reducing friction and wear.

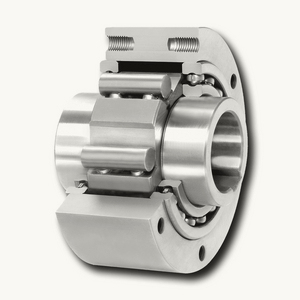

Key Components of Bearings

Understanding the basic components of bearings can help in grasping their functionalities:

- Inner Race: The inner ring of the bearing which fits onto the rotating shaft.

- Outer Race: The outer ring which holds the bearing in place within the housing.

- Rolling Elements: Balls or rollers that facilitate movement. The design of these elements varies based on the type of bearing.

- Separator: Also known as a cage, it keeps the rolling elements evenly spaced, reducing wear and ensuring smooth operation.

- Lubrication: A crucial element that reduces friction, extends lifespan, and ensures optimal performance.

Types of Bearings

Bearings can be categorised into various types based on their design, load capacity, and the nature of motion. Here’s a brief overview of the most common types:

Ball Bearings

Ball bearings are one of the most widely used types. They consist of a series of small balls enclosed between the inner and outer races. Ideal for high-speed applications, these bearings can handle both radial and axial loads. They are commonly found in motors, gearboxes, and various automotive applications.

Roller Bearings

Roller bearings use cylindrical rollers instead of balls. This design offers a larger contact area with the raceways, allowing them to carry heavier loads compared to ball bearings. They are generally used in applications where substantial radial loads are present.

Needle Bearings

A type of roller bearing, needle bearings are characterised by their long, thin rollers, which allow them to have a very low profile. This makes them an excellent choice for applications with limited space but high load capacity requirements, such as automotive transmissions.

Thrust Bearings

Thrust bearings are designed to handle axial loads while providing minimal friction. They can be ball or roller type and are typically used in applications involving heavy vertical loads, like in cranes or large rotary equipment.

Applications of Bearings

Bearings are ubiquitous in modern machinery and devices. Here are some key industries and applications where bearings play a vital role:

Automotive Industry

In vehicles, bearings are found in the engine, wheel hubs, transmission, and suspension systems, ensuring smooth operation and stability.

Aerospace

Bearings are crucial in aircraft, from engines to landing gear, enabling the reliable performance of various mechanisms in harsh conditions.

Industrial Machinery

Almost all machinery, from conveyor belts to lathes, employs bearings to facilitate movement and enhance productivity.

Consumer Electronics

Small and efficient bearings are integral to the operation of gadgets like hard drives, fans, and printers, contributing to their durability and performance.

Choosing the Right Bearing

Selecting the right bearing for your application is vital for ensuring optimum performance and longevity. Here are some key considerations:

Load Capacity

Understanding the types of loads your bearing will encounter - whether they are radial, axial, or a combination of both - is crucial. Ensure the bearing you choose can handle these loads comfortably.

Speed Requirements

Different bearings are rated for specific speed limits. Assess your application's operational speed and select a bearing that can reliably handle those conditions.

Operating Environment

The environment in which the bearing operates can significantly influence its performance. Consider factors such as temperature, humidity, and exposure to contaminants when selecting your bearing.

Maintenance Intervals

Some bearings require regular maintenance and lubrication, while others, like sealed bearings, may never need maintenance. Determine your capacity for ongoing maintenance when making your choice.

Maintenance of Bearings

Proper maintenance of bearings is vital to prolonging their lifespan and maintaining efficient operation. Regular inspections, cleaning, and timely lubrication can prevent premature failure. Here are some maintenance tips to consider:

Regular Inspections

Frequent checks can help identify issues such as wear, corrosion, or improper lubrication before they escalate into more significant problems.

Cleanliness

Keeping bearings clean prevents dirt and debris from causing wear and tear. Use appropriate cleaning agents and techniques to ensure no residue is left behind.

Lubrication

Proper lubrication is key to ensuring smooth operation. Use the recommended lubricant for your specific type of bearing and apply it adequately to reduce friction and heat generation.

Temperature Monitoring

Bearings operating in high temperatures can degrade rapidly. Monitoring the temperature during operation can help spot early signs of trouble.

Understanding Bearings and Their Importance

Bearings are the unsung heroes behind the scenes of many machines and devices. Their ability to facilitate movement while reducing friction enables the technological advancements we enjoy today, from transportation to manufacturing innovations. Understanding their types, functions, and maintenance is essential for individuals and industries that rely on these components.

Investing in high-quality bearings tailored to specific applications is paramount. By taking into account factors like load, speed, and environmental conditions, you ensure that your machinery operates efficiently and problem-free.

Bearings are more than just metal and grease; they power the machinery that makes modern life possible. So, the next time you turn on a gadget or drive a car, remember the intricate bearings working tirelessly behind the scenes. Embrace the knowledge of bearings and witness how this understanding transforms your approach to maintenance and machine design.